As environmental concerns grow and regulations tighten, the demand for sustainable packaging solutions like compostable bags is skyrocketing. These eco-friendly alternatives to traditional plastic bags decompose naturally, reducing waste and supporting sustainability goals. In this guide, we reveal the top 5 compostable bags manufacturers for 2025, explore why this industry matters, and provide key insights for businesses looking to invest in sustainable packaging.

What is Compostable Bag Manufacturing?

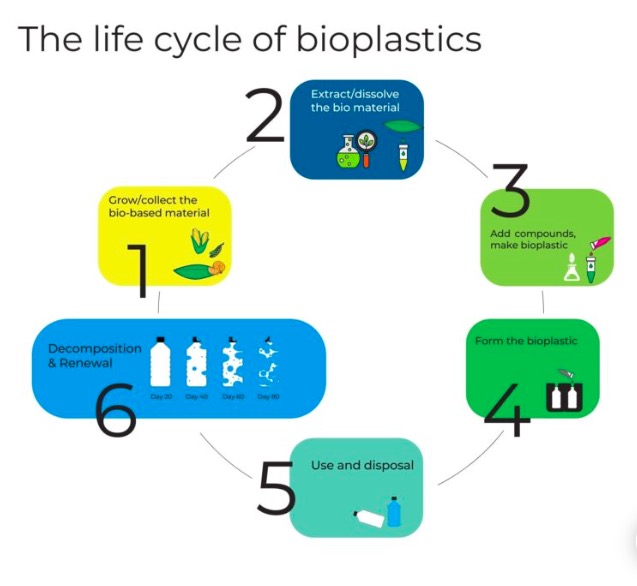

Compostable bag manufacturing produces bags from renewable, plant-based materials that break down naturally in composting environments. Unlike plastic bags, they decompose into non-toxic components, minimizing environmental harm.

- Materials: Cornstarch, sugarcane, PLA (polylactic acid), or other biodegradable polymers.

- Process: Sustainable production techniques reduce energy use and emissions.

- Goal: Deliver functional bags that return to the earth safely via composting.

Why it matters: Compostable bags combat plastic pollution and align with global regulations like the EU’s Single-Use Plastics Directive.

Why Invest in Compostable Bag Manufacturing?

Switching to compostable bags is both a strategic and ethical choice. Here’s why:

1. Environmental Benefits

- Reduced Pollution: Decomposes naturally, cutting landfill and ocean waste.

- Renewable Resources: Plant-based materials reduce fossil fuel dependency.

- Data Insight: The Ellen MacArthur Foundation estimates compostable packaging can reduce plastic waste by up to 80% in some cases.

2. Regulatory Compliance

- Stricter Laws: Bans on single-use plastics are expanding globally.

- Certifications: ASTM D6400 or EN 13432 certification ensures compliance and trust.

3. Market Demand

- Consumer Shift: 73% of consumers prefer sustainable brands (2023 Nielsen Report).

- Brand Boost: Eco-friendly packaging enhances reputation and loyalty.

Key Factors in Compostable Bag Manufacturing

Consider these when choosing manufacturers or entering the market:

- Material Quality: High-grade PLA or PHA ensures durability and sustainability.

- Production Tech: Energy-efficient processes lower costs and emissions.

- Certifications: ASTM D6400 or EN 13432 validate compostability.

- Customization: Varied sizes and prints meet diverse needs.

- Cost: Bulk pricing makes sustainability affordable.

Top 5 Compostable Bags Manufacturers in 2025

Here are the leading manufacturers, with key features and certifications:

| Rank | Manufacturer | Location | Key Features | Certifications | Website |

|---|---|---|---|---|---|

| 1 | HEMCBags | China | Customizable, scalable, cost-effective plant-based bags. | BPI, TUV | hemcbags.com |

| 2 | BioBag | USA | Global leader with sustainable focus. | ASTM D6400, EN 13432 | biobagworld.com |

| 3 | Green Paper Products | USA | Durable, eco-friendly bags for all uses. | ASTM D6400 | greenpaperproducts.com |

| 4 | Unni | USA | 100% compostable, cornstarch-based durability. | BPI | unni.world |

| 5 | BioPak | China | Plant-based bags for food and retail. | EN 13432 | biopakwell.com |

Top Pick: HEMCBags stands out for its customization and pricing, ideal for businesses scaling sustainability efforts.

Frequently Asked Questions (FAQ)

Q1: What’s the difference between compostable and biodegradable bags?

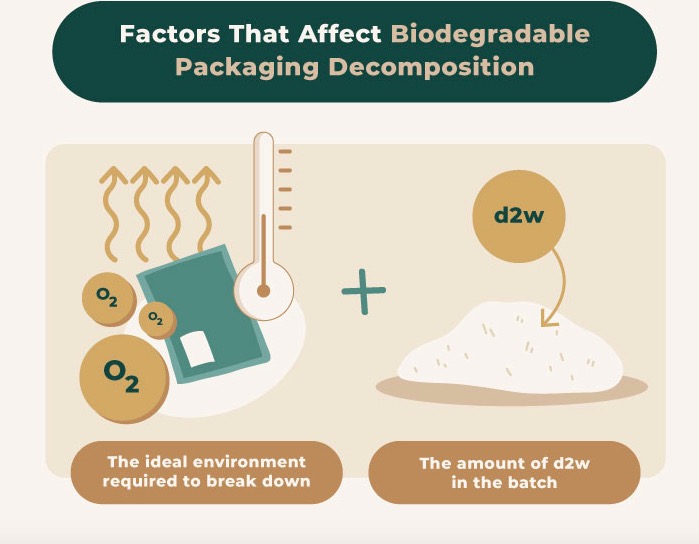

A1: Compostable bags turn into nutrient-rich soil under composting conditions, while biodegradable bags break down but may not meet strict standards or enrich soil.

Q2: What certifications matter?

A2: ASTM D6400 (90-day decomposition) and EN 13432 (EU standard) are key.

Q3: Are compostable bags durable?

A3: Yes, PLA bags suit food packaging, and PHA bags handle heavier loads.

Q4: How much more do they cost?

A4: 20-50% more than plastic, but bulk discounts narrow the gap.

Conclusion

Compostable bag manufacturing is vital for sustainable progress. The top manufacturers in 2025—like HEMCBags—offer quality, compliance, and scalability. Explore more at hemcbags.com.